- ALL COMPUTER, ELECTRONICS AND MECHANICAL COURSES AVAILABLE…. PROJECT GUIDANCE SINCE 2004. FOR FURTHER DETAILS CALL 9443117328

Projects > MECHANICAL/AUTOMOBILE > 2017 > FABRICATION > AUTOMOBILE

The aim of the project is to design and fabrication of an anti-lock braking system. ABS is a safety system which prevents the wheels on a motor vehicle from locking up (or ceasing to rotate) while braking. ABS means a portion of service brake System that automatically controls the Degree of rotational wheel slip during Braking. The ABS electrically controls the brake fluid pressure to each wheel to prevent the wheel from locking during braking on slippery road surfaces, thereby enabling the driver to maintain the directional control. If the ABS becomes inoperative, a fail-safe system is activated to ensure same level of braking performance as with a conventional brake system. In that case, the warning light comes on to indicate that the ABS is malfunctioning. The braking system of a car is undoubtedly one of its more important features. The aim of this work is to create a better braking system with display. The speed of the vehicle is sensed by IR sensor. The IR sensor sends the speed data to the microcontroller. The microcontroller analyses the speed and accordingly it sends data to the LCD display. When the user applies the brake, if the speed exceeds the particular level, the microcontroller operates the additional brake(Electromagnetic brake) with the disc brake. Thus the over speed is controlled. Since microcontroller is used for controlling the brake, the operations are very accurate

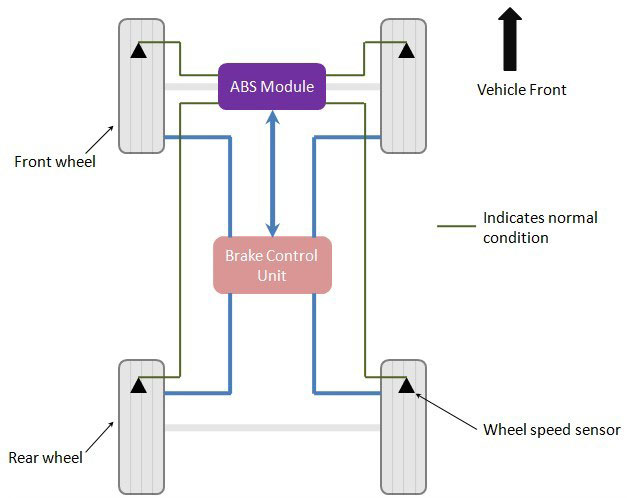

Block Diagram

Line Diagram